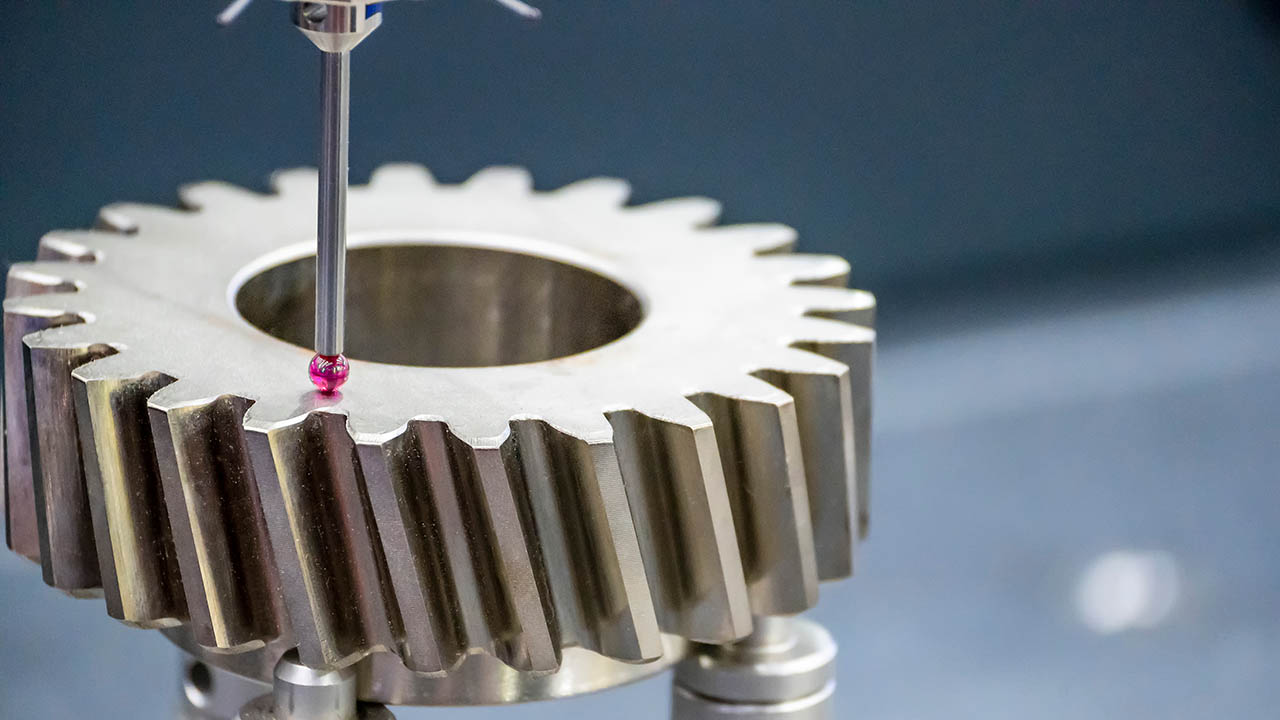

Description

Overall Equipment Effectiveness (OEE) is the most commonly used manufacturing metric to understand, measure, and improve current performance. OEE is measured by combining a machine’s performance, availability, and quality. In this way, OEE helps to identify potential losses and understand where a process is falling short. On the other hand, Total Effective Equipment Performance (TEEP) is a performance metric that provides insights as to the true capacity of the manufacturing operation. It takes account both equipment losses and schedule losses.

- OEE measures the percentage of Planned Production Time that is truly productive.

- TEEP measures the percentage of all time that is truly productive.

The importance of understanding OEE and TEEP is essential so one can accurately forecast, plan and schedule the production of his industrial production line. Based on these metrics, one can schedule with high degree of accuracy what his/her industry can manufacture for its customers.